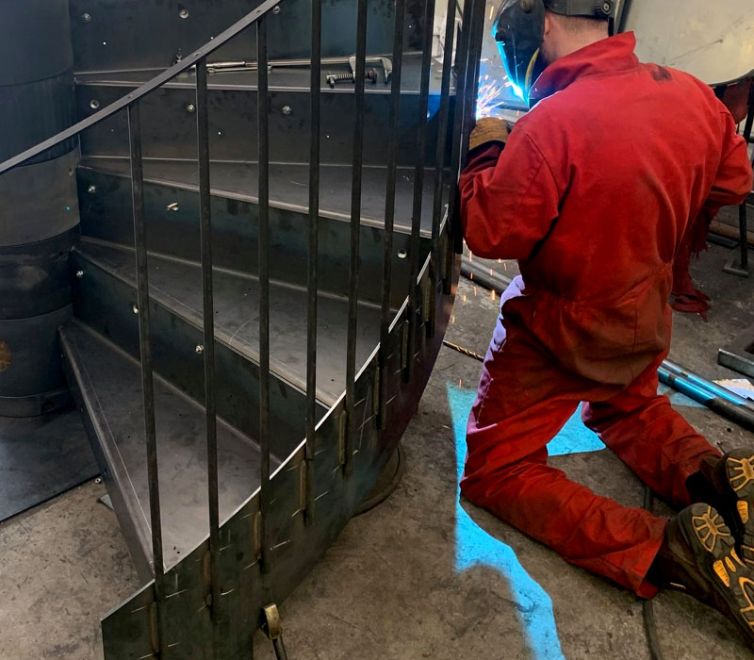

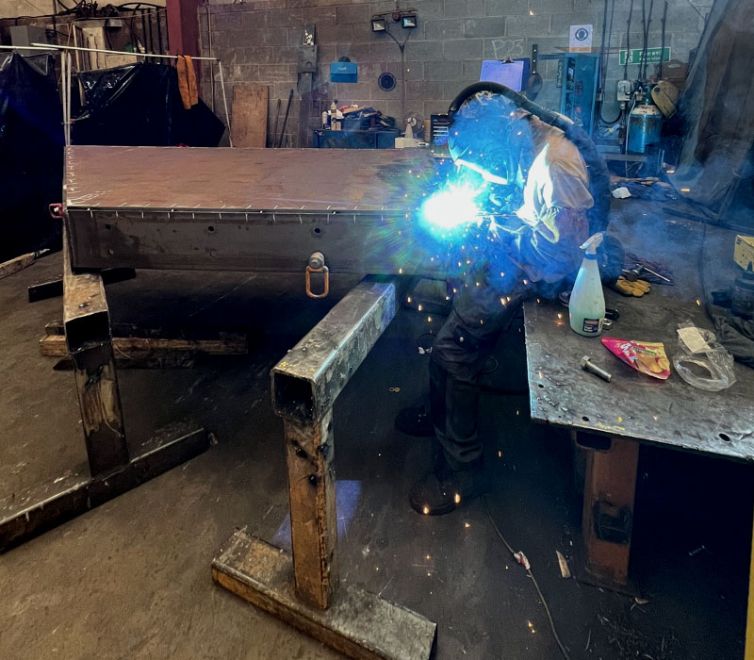

Welding Processes

Certified Procedures by Skilled Professionals

high quality welding processes and comprehensive capabilities to deliver safe, specification-compliant services for structural steel fabrication and precision engineering applications.

Welding Processes & Capabilities

At Premier Engineering (Yorkshire) Ltd, we take pride in offering high-quality welding services backed by certified procedures and skilled professionals. We operate a fully controlled working environment and ensure all work is carried out in accordance with the latest industry standards and client-specific requirements. We employ a variety of techniques to suit different materials, thicknesses, and applications. Each method is selected based on project demands, ensuring the highest level of accuracy, penetration, and finish, these are inclusive of:

MAGS

Metal Active Gas Welding

MAGS (Metal Active Gas Welding) – Also known as Semi-Automatic Shielded Metal Arc Welding, ideal for general fabrication and structural work due to its speed and versatility.

TIG

Tungsten Inert Gas Welding

TIG (Tungsten Inert Gas Welding) – A precise method suited to thinner materials and high-specification finishes, commonly used with stainless steel, aluminium, and exotic alloys.

MMA

Manual Metal Arc Welding

MMA (Manual Metal Arc Welding) – Also known as stick Weld, this process is highly effective for outdoor or heavy-duty applications, especially on thicker sections.

Certified Welders & Procedures

All of our welders are fully approved to BS EN ISO 9606 and regularly monitored by our Responsible Welding Coordinator (RWC). Quality and consistency are maintained through strict in-house checks and supervision, ensuring every weld meets regulatory and client expectations. Welding Procedure Qualification Records (WPQRs) and Welding Procedure Specifications (WPSs) are all certified by UKAS-accredited third-party bodies, providing full traceability and compliance.

These certifications are available for client review prior to project commencement for full transparency.

Extensive Welding Processes

We maintain a wide-ranging library of UKAS-approved WPQRs, covering an array of materials and applications: Procedures in line with BS EN ISO 15614, including small-diameter pipework, thin and thick plate welding. Qualification for welding down to -20°C on carbon plate and pipe. Proven processes for materials from 1mm to 100mm in thickness. Expertise across carbon steel, stainless steel, duplex stainless, and aluminium.

For more information and enquiries…

Commitment to Quality & Compliance

We work continuously to ensure that all processes meet the latest standards and operational requirements. Our team is committed to expanding qualifications and updating procedures to support changing industry needs and client specifications.

Whether you’re looking for coded welding on structural steel, pressure pipework, or bespoke fabrication, Premier Engineering in Barnsley (South Yorkshire) delivers safe, certified, and expertly executed results every time.